Takaitaccen Bayani

Dole ne man shanu na biredi ya zama filastik kuma mai ɗorewa. Ana iya shirya tsarin samar da man shanu na biredi cikin sauƙi ta hanyar amfani da bututun chiller (mai musayar zafi mai siffar tubular). A lokacin sarrafa mai, sanyaya yana da tasiri mai mahimmanci akan yadda man shanu ke yin biredi. Margarine daban-daban yana buƙatar yanayi daban-daban na tsari da yanayin zafi.

Dole ne man shanu na biredi ya zama filastik kuma mai ɗorewa. Ana iya shirya tsarin samar da man shanu na biredi cikin sauƙi ta hanyar amfani da bututun chiller (mai musayar zafi mai siffar tubular). A lokacin sarrafa mai, sanyaya yana da tasiri mai mahimmanci akan yadda man shanu ke yin biredi. Margarine daban-daban yana buƙatar yanayi daban-daban na tsari da yanayin zafi.

Kalmomi masu mahimmanci: margarine na biredi; ganga mai sanyi; injin sanyaya bututu, mai musayar zafi a saman da aka goge, samar da margarine.

Gabatarwar fasaha ta bututun chiller

Duk da cewa kayayyakin margarine masu laushi sun daɗe suna samarwa, mutane suna ƙoƙarin gano hanya mafi kyau don yanayin aiki, musamman akan yadda ake yin amfani da dabarar samfura daban-daban a ƙarƙashin yanayi daban-daban na sarrafawa. Kafin ƙirƙirar na'urar musayar zafi ta scraper, ko injin kashe bututu, duk samfuran margarine ana samar da su ne ta amfani da injin kashe ganga da mannewa. Saboda na'urar sarrafa bututun kashe bututun yana da fa'idodi da yawa idan aka kwatanta da sauran na'urorin sarrafawa, don haka yanzu masana'antun margarine suna amfani da samar da margarine mai laushi, wannan takarda akan injin sarrafa bututun kashe bututun don samar da tsarin margarine mai laushi don yin gabatarwa.

Babban halayen margarine mai laushi shine ƙarfinsa da kuma kwanciyarsa. Idan aka naɗe margarine aka kuma naɗe shi akai-akai, dole ne yadudduka su kasance ba tare da karyewa ba a cikin kullu, don haka ƙarfinsa yana da mahimmanci; Daidaito ma yana da mahimmanci. Idan margarine bai yi ƙarfi sosai ba har ya zama mai laushi ko kuma mai zai iya ratsawa, kuma ya shiga cikin kullu, za a rage yawan mai da ke tsakanin kullu.

Tsarin injin kashe ganga mai juyawa abu ne mai sauƙi, sai dai a daidaita wasu sigogi kaɗan a samarwa. Margarine mai laushi da injin kashe ganga ke samarwa yana da kyakkyawan filastik, ba shi da sauƙin shiga mai, kuma yana da ƙarfi sosai a cikin babban zafin jiki. Injin kashe bututu fiye da injin kashe ganga a cikin aiki ya sami ci gaba mafi girma, wanda galibi yana nuna a cikin:

(1) A cikin kayayyakin sarrafa bututun da aka rufe, kyakkyawan rufewa, yanayin tsafta suma zasu inganta sosai;

(2) Fahimtar aikin matsi mai yawa, wanda yake da mahimmanci musamman don samar da margarine mai kauri;

(3) Kyakkyawan sassauci, zai iya canza saurin, matsin lamba, ƙarfin daskarewa da sauran yanayin aiki cikin sauƙi.

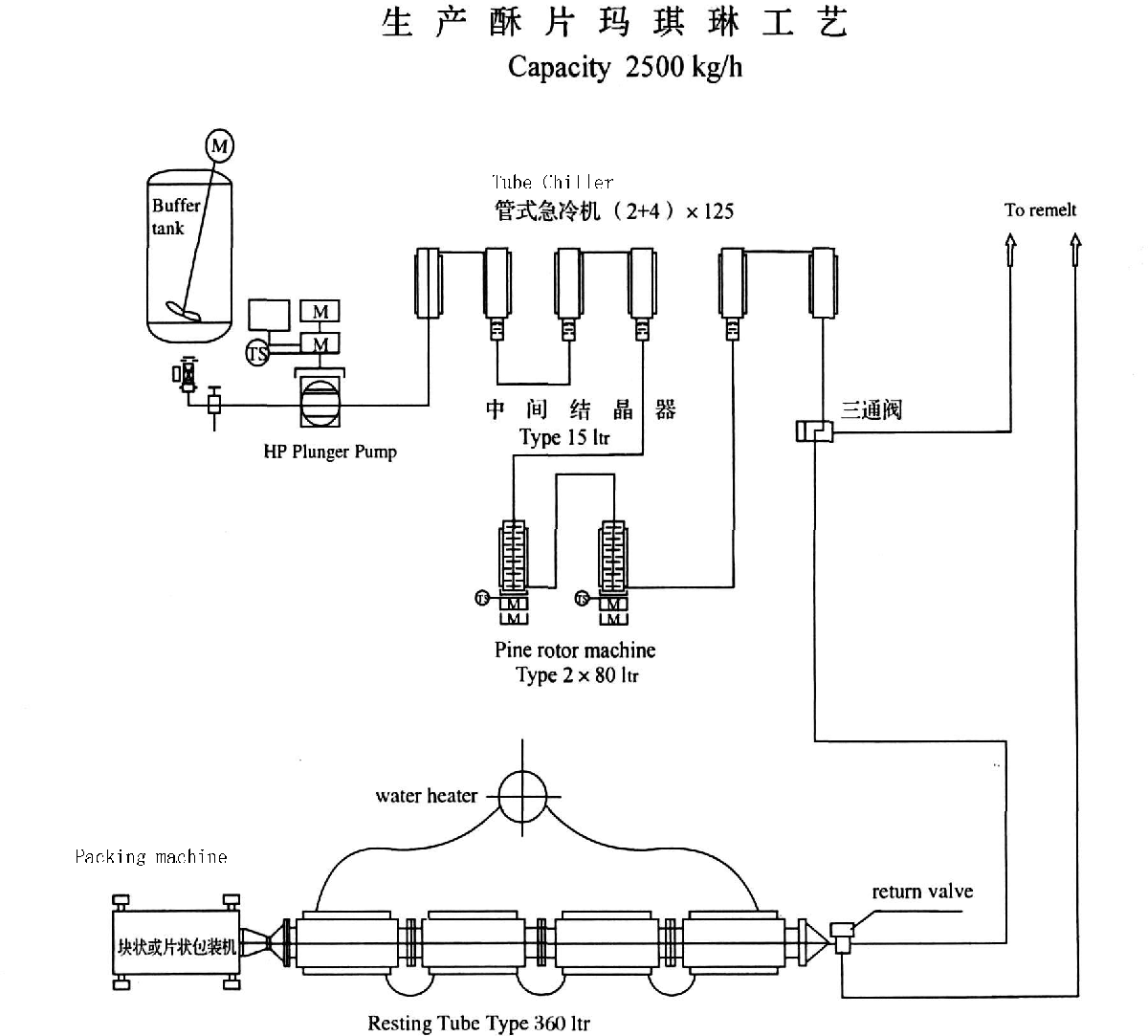

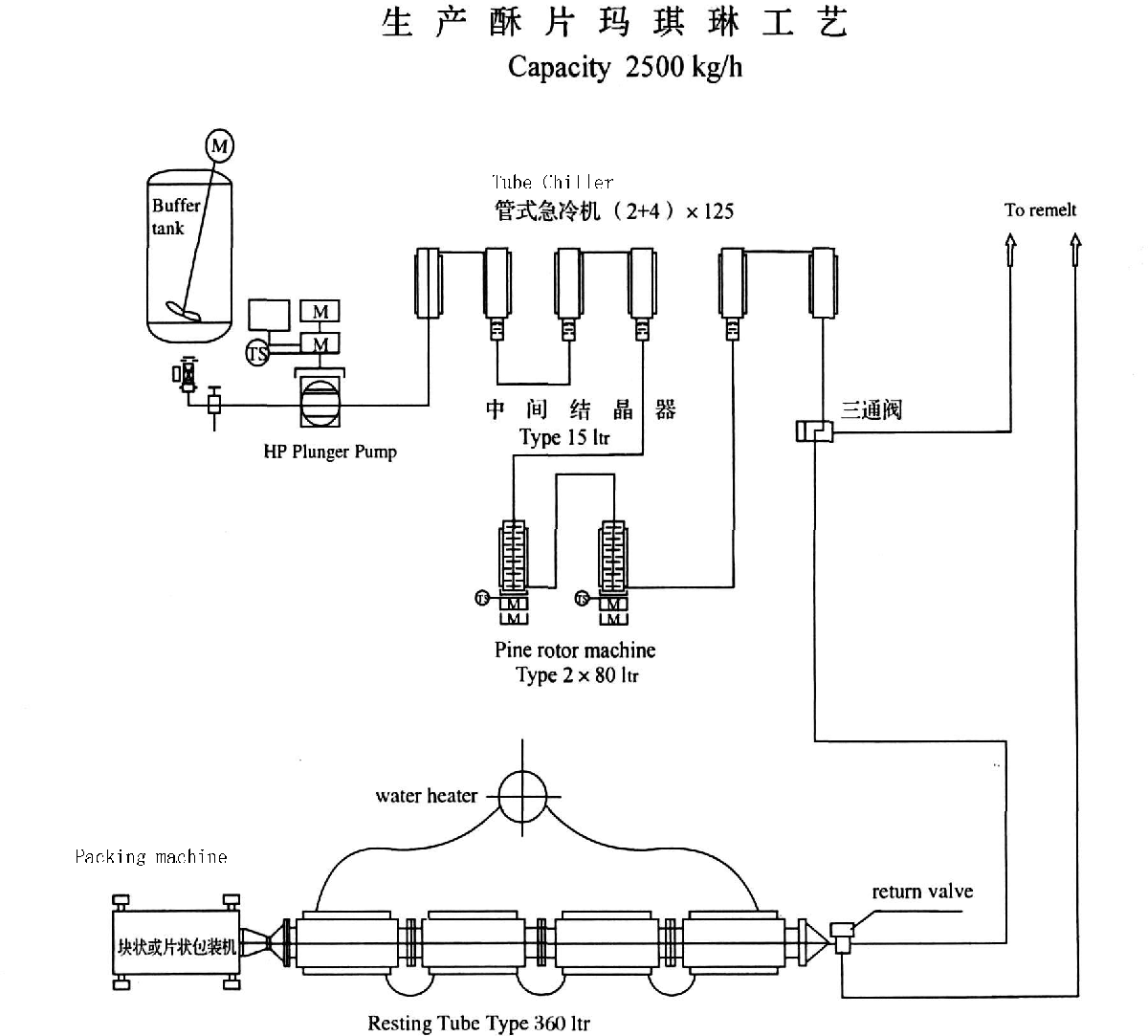

Tsarin da ake amfani da shi wajen samar da margarine mai laushi ta hanyar injin kashe bututu shine kamar haka:

Famfon mai matsa lamba mai yawa ※ Mai musayar zafi mai ƙarfi mai ƙarfi (Raka'a A) ※ Saitin mai lu'ulu'u mai matsakaici ※ Injin rotor mai juyawa (Raka'a B)※ Babban bututun hutawa mai iya ɗaukar nauyi ※ Shiryawa yanka/toshe.

Aikin mai haɗakar crystallizer yayi daidai da na mai haɗakar ƙwanƙwasa. Yana kan bututun kashe wuta na injin sarrafawa kuma ana tura shi ya juya ta hanyar shaft ɗin mai yankewa na injin sarrafawa.

Yana da sauƙi a daidaita tsarin sarrafa samfurin don samar da margarine mai laushi tare da injin kashe bututu. Manufar daidaita tsarin za a iya cimma ta hanyar canza yanayin haɗin bututun haɗawa tsakanin rukunin bututun kashe bututu (raka'a A) da na'urar ƙulla (raka'a B), wanda ya fi sauƙin aiki. Misali, ana iya sanya na'urar ƙullawa (raka'a B) a tsakiyar bututun kashe bututun A, bin kwararar A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, ko canzawa zuwa kwararar A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. Ta hanyar canza tsarin sarrafawa kawai zai iya inganta ingancin samfur. A cikin tsarin da ke sama, tsarin sanya na'urar B a tsakiyar bututun kashe bututun A ya dace musamman don tsarin man kayan lambu bisa ga man dabino, wanda aka tabbatar sau da yawa a cikin aikin samarwa. Kuma idan babban kayan samfurin shanu ne, ana iya samun sakamako mafi kyau ta hanyar sanya naúrar B bayan naúrar A.

Ana ƙayyade ƙarfin murƙushewa ta hanyar ƙirƙirar samfurin, misali, ya kamata a yi amfani da babban ƙarfin murƙushewa don ƙirƙirar mai tare da lu'ulu'u a hankali. A cikin tsarin samar da bututun sanyaya cikin sauri, tasirin murƙushewa shine ƙarfin rukuni na tsakiya da ƙarfin lu'ulu'u da kuma bugun sashin murƙushewa (B) jimlar ƙarfin naúrar, don haka lokacin da canji a cikin dabarar samfurin, yana buƙatar daidaita ƙarfin murƙushewa, ko dai ta hanyar ƙarfin naúrar B ya karu ko ya ragu, zai iya ƙaruwa ko ya ragu a cikin ƙarfin mold na tsakiya, Har ma ana iya yin hakan ta hanyar ƙarawa da cirewa a lokaci guda, mai sassauƙa sosai.

Ana ƙayyade ƙarfin murƙushewa ta hanyar ƙirƙirar samfurin, misali, ya kamata a yi amfani da babban ƙarfin murƙushewa don ƙirƙirar mai tare da lu'ulu'u a hankali. A cikin tsarin samar da bututun sanyaya cikin sauri, tasirin murƙushewa shine ƙarfin rukuni na tsakiya da ƙarfin lu'ulu'u da kuma bugun sashin murƙushewa (B) jimlar ƙarfin naúrar, don haka lokacin da canji a cikin dabarar samfurin, yana buƙatar daidaita ƙarfin murƙushewa, ko dai ta hanyar ƙarfin naúrar B ya karu ko ya ragu, zai iya ƙaruwa ko ya ragu a cikin ƙarfin mold na tsakiya, Har ma ana iya yin hakan ta hanyar ƙarawa da cirewa a lokaci guda, mai sassauƙa sosai.

Lokacin Saƙo: Disamba-30-2021