Fasahar Samar da Margarine

TAKAITACCEN EXECUTIVE

Kamfanonin abinci a yau sun kasance kamar sauran masana'antun masana'antu ba wai kawai suna mai da hankali kan aminci da ingancin kayan sarrafa abinci ba har ma da ayyuka daban-daban waɗanda mai samar da kayan sarrafa kayan zai iya bayarwa. Baya ga ingantattun layukan sarrafawa da muke bayarwa, za mu iya zama abokin tarayya daga ra'ayin farko ko matakin aikin zuwa lokacin ƙaddamarwa na ƙarshe, kar a manta da sabis na bayan kasuwa mai mahimmanci.

Shiputec yana da ƙwarewar fiye da shekaru 20 don masana'antar sarrafa abinci da tattara kaya.

GABATARWA GA FASSARAR MU

HANNU DA ALKAWARI

Tsarin sassan Shiputec, masana'antu da kasuwanni suna aiwatar da aikin injiniya da mafita ta atomatik ga kiwo, abinci, abin sha, marine, magunguna da masana'antar kulawa ta sirri ta hanyar ayyukan sa na duniya.

Mun himmatu wajen taimaka wa abokan cinikinmu a duk faɗin duniya don haɓaka aiki da ribar masana'antar masana'anta da tafiyar matakai. Mun cimma wannan ta hanyar samar da samfurori da yawa da mafita daga kayan aikin injiniya don tsara cikakkun tsire-tsire masu aiki da goyan bayan aikace-aikacen jagorancin duniya da ƙwarewar ci gaba.

Muna ci gaba da taimaka wa abokan cinikinmu haɓaka aiki da ribar shukar su a duk tsawon rayuwar sabis ɗin tare da sabis na tallafi wanda aka keɓance ga kowane buƙatun su ta hanyar haɗin gwiwar sabis na abokin ciniki da cibiyar sadarwar kayan gyara.

MANUFAR CUSTOMA

Shiputec yana haɓaka, ƙera da girka layukan sarrafawa na zamani, ingantaccen inganci kuma abin dogaro ga masana'antar abinci. Don samar da samfuran kitse mai ƙirƙira kamar margarine, man shanu, yadawa da gajarta Shiputec yana ba da mafita wanda kuma ya ƙunshi layin tsari don samfuran kayan abinci na emulsified kamar mayonnaise, biredi da sutura.

MAGANAR MARGARINE

Margarine da samfuran da ke da alaƙa sun ƙunshi lokaci na ruwa da lokacin mai kuma ana iya siffanta su azaman ruwa-in-man (W / O) emulions wanda lokacin ruwan ya tarwatse sosai azaman droplets a cikin ci gaba da mai. Dangane da aikace-aikacen samfurin, an zaɓi abun da ke ciki na lokaci mai kitse da tsarin masana'anta daidai.

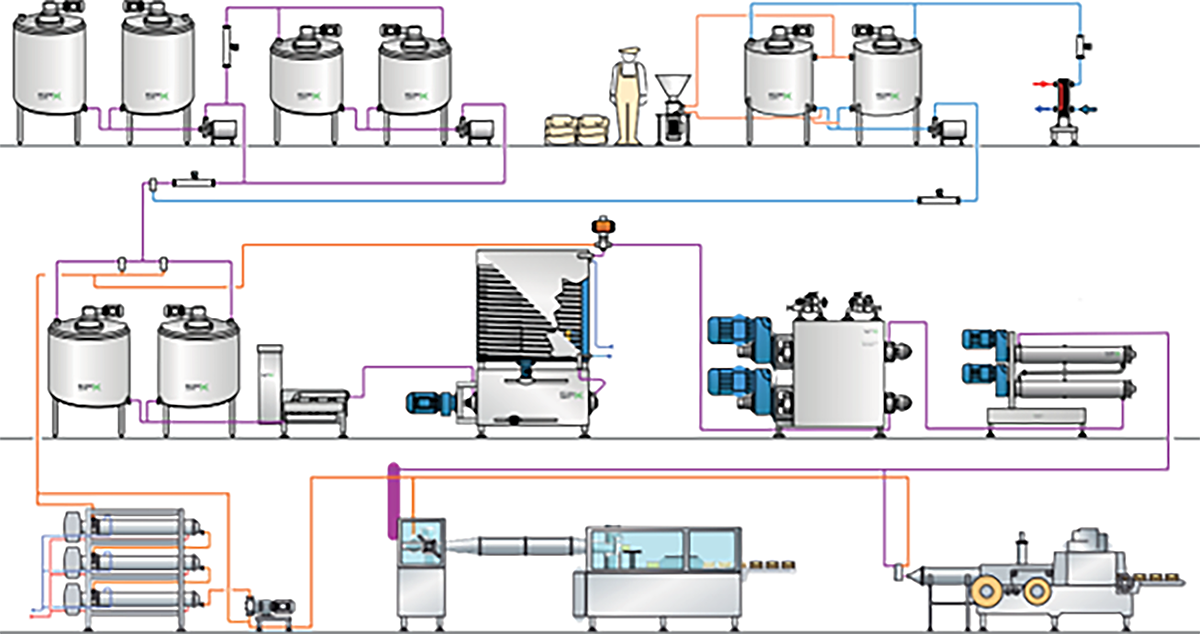

Baya ga kayan aikin crystallization, kayan aikin masana'antu na zamani don margarine da samfuran da ke da alaƙa za su haɗa da tankuna daban-daban don ajiyar mai da kuma emulsifier, lokaci na ruwa da shirye-shiryen emulsion; Ana ƙididdige girman da adadin tankuna bisa ga ƙarfin shuka da fayil ɗin samfur. Har ila yau, wurin ya haɗa da na'ura mai kula da kiwo da wurin sake narkewa. Don haka, tsarin kera gaba ɗaya za a iya raba shi zuwa ƙananan matakai masu zuwa (don Allah a duba zane na 1):

SHIRI NA SHAFIN RUWA DA MATSALAR FAT (ZONE 1)

Yawancin lokaci na ruwa ana shirya batch-hikima a cikin tanki na ruwa. Ya kamata ruwan ya kasance da ingancin sha. Idan ba za a iya tabbatar da ingancin ruwan sha ba, ana iya fuskantar ruwan kafin a yi masa magani ta hanyar misali UV ko tsarin tacewa.

Baya ga ruwa, lokaci na ruwa zai iya ƙunshi gishiri ko brine, sunadaran madara (margarine tebur da ƙananan shimfidawa), sukari (fari mai laushi), masu ƙarfafawa (raguwa da ƙananan shimfidawa), masu kiyayewa da ruwa mai narkewa.

Manyan sinadirai a cikin lokaci mai kitse, gaurayawan kitse, yawanci sun ƙunshi cakuda mai da mai daban-daban. Don cimma margarine tare da halaye da ayyuka da ake so, rabon mai da mai a cikin cakuda mai yana da yanke hukunci don aikin samfurin ƙarshe.

Kitse da mai iri-iri, ko dai a matsayin cakuda mai ko mai guda ɗaya, ana adana su a cikin tankunan ajiyar mai da aka saba sanyawa a wajen wurin samar da man. Ana ajiye waɗannan a cikin kwanciyar hankali na ma'auni sama da wurin narkewar kitsen da kuma tashin hankali don guje wa raguwar kitsen da kuma ba da damar sarrafawa cikin sauƙi.

Baya ga gauran kitse, lokacin mai yawanci ya ƙunshi ƙananan sinadarai masu narkewa kamar emulsifier, lecithin, dandano, launi da antioxidants. Wadannan ƙananan sinadarai suna narkar da su a cikin kitsen mai kafin a kara lokacin ruwa, don haka kafin tsarin emulsification.

SHIRIN EMULSION (ZONE 2)

An shirya emulsion ta hanyar canja wurin mai daban-daban da mai ko mai gauraya zuwa tankin emulsion. Yawancin lokaci, ana ƙara yawan kitse mai narkewa ko gaurayawan kitse da farko sannan a fara ƙara ƙananan kitse mai narkewa da mai mai ruwa. Don kammala shirye-shiryen lokaci mai kitse, ana ƙara emulsifier da sauran ƙananan sinadaran mai mai narkewa zuwa gauraya mai. Lokacin da aka haɗu da duk abubuwan da ake buƙata don lokacin mai da kyau, ana ƙara lokacin ruwa kuma an ƙirƙiri emulsion a ƙarƙashin haɗuwa mai ƙarfi amma sarrafawa.

Daban-daban tsarin za a iya amfani da metering daban-daban sinadaran ga emulsion wanda biyu suna aiki batch-hikima:

Tsarin mita mai gudana

Tsarin tanki mai nauyi

A ci gaba a-line emulsification tsarin ne kasa fi so amma amfani da bayani a misali high iya aiki Lines inda iyaka sarari ga emulsion tankuna yana samuwa. Wannan tsarin yana amfani da famfunan allurai da mitoci masu kwarara don sarrafa rabon matakan da aka ƙara a cikin ƙaramin tanki na emulsion.

Tsarukan da aka ambata a sama duk ana iya sarrafa su ta atomatik. Wasu tsofaffin tsire-tsire, duk da haka, har yanzu suna sarrafa tsarin shirye-shiryen emulsion da hannu amma waɗannan suna da wahala kuma ba a ba da shawarar shigar da su a yau ba saboda ƙaƙƙarfan ƙa'idodin ganowa.

Tsarin mita ya kwarara ya dogara ne akan shirye-shiryen emulsion mai hikima wanda a cikin nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan ana auna su ta hanyar mitoci masu gudana lokacin da aka canza su daga tankunan shirye-shiryen lokaci daban-daban a cikin tankin emulsion. Daidaiton wannan tsarin shine +/- 0.3%. Wannan tsarin yana da alaƙa da rashin jin daɗinsa ga tasirin waje kamar girgiza da datti.

Tsarin tanki mai auna yana kama da tsarin mita mai gudana dangane da shirye-shiryen emulsion mai hikima. Anan ana ƙara adadin sinadirai da matakai kai tsaye zuwa tankin emulsion wanda aka ɗora akan sel masu ɗaukar nauyi wanda ke sarrafa adadin da aka ƙara a cikin tanki.

Yawanci, ana amfani da tsarin tanki guda biyu don shirya emulsion don samun damar gudanar da layin crystallization ci gaba. Kowane tanki yana aiki azaman shiri da buffer tank (tankin emulsion), don haka za a ciyar da layin crystallization daga tanki ɗaya yayin da za a shirya sabon tsari a ɗayan kuma akasin haka. Ana kiran wannan tsarin juya-flop.

Magani inda aka shirya emulsion a cikin tanki ɗaya kuma lokacin da aka shirya an canza shi zuwa tanki mai buffer daga inda ake ciyar da layin crystallization shima zaɓi ne. Ana kiran wannan tsarin tsarin premix/buffer.

PASTEURIZATION (ZONE 3)

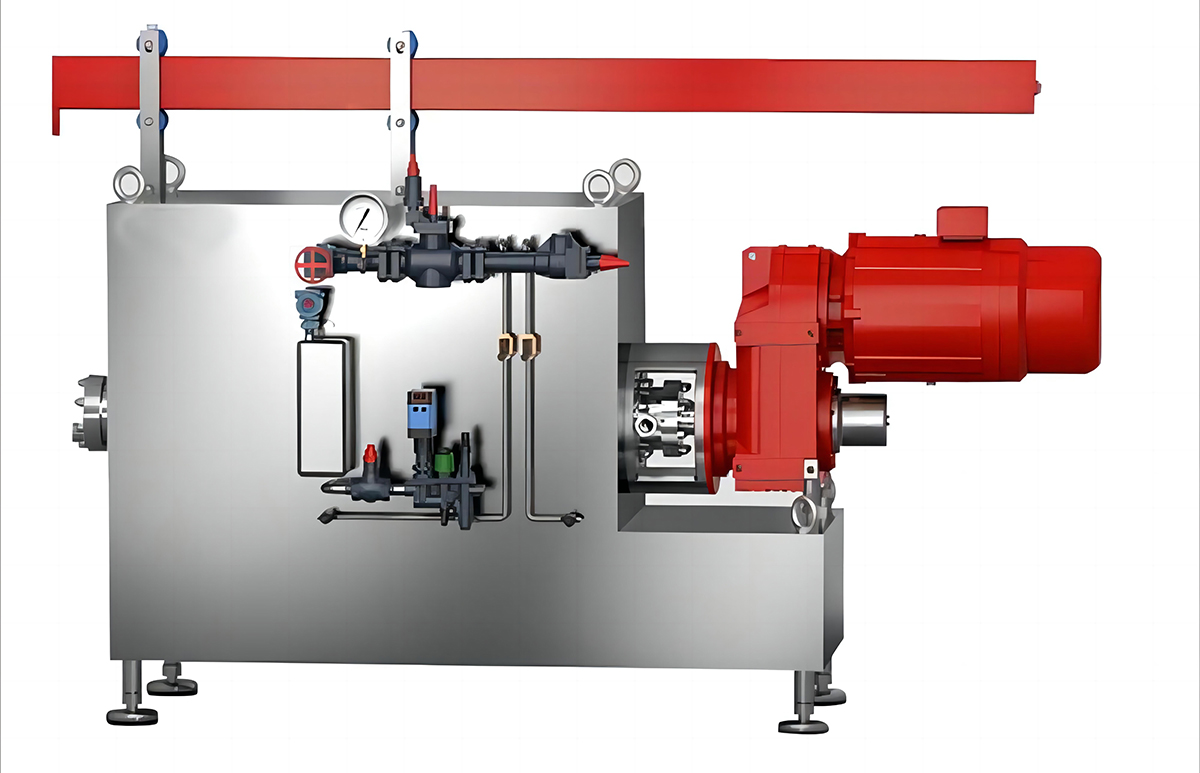

Daga tanki buffer da emulsion da aka kullum ci gaba da pumped ta ko dai farantin zafi Exchanger (PHE) ko wani low matsa lamba scraped surface zafi Exchanger (SSHE), ko babban matsa lamba SSHE for pasteurization kafin shigar da crystallization line.

Don cikakkun samfuran mai ana amfani da PHE galibi. Don ƙananan nau'ikan kitse inda ake sa ran emulsion zai nuna ɗanɗano mai ɗanɗano da ɗanɗano mai ƙarfi kuma don emulsions masu zafin zafi (misali emulsions tare da babban abun ciki mai gina jiki) tsarin SPX azaman matsakaicin matsakaicin matsa lamba ko SPX-PLUS azaman babban maganin matsa lamba ana bada shawarar.

Tsarin pasteurization yana da fa'idodi da yawa. Yana tabbatar da hana haɓakar ƙwayoyin cuta da haɓakar sauran ƙananan ƙwayoyin cuta, don haka inganta yanayin kwanciyar hankali na emulsion. Pasteurization na ruwa lokaci ne mai yuwuwa, amma pasteurization na cikakken emulsion an fi son tun pasteurization tsari na emulsion zai mini-rasa lokacin zama daga pasteurized samfurin zuwa cika ko shiryawa na karshe samfurin. Har ila yau, ana kula da samfurin a cikin tsarin layi daga pasteurization zuwa cikawa ko tattarawar samfurin ƙarshe da kuma pasteurization na duk wani kayan aikin sake yin aiki lokacin da aka yi amfani da cikakken emulsion.

Bugu da kari, pasteurization na cikakken emulsion tabbatar da cewa emulsion aka ciyar da crystallization line a akai zazzabi cimma m aiki sigogi, samfurin yanayin zafi da samfurin texture. Bugu da kari, abin da ya faru na pre-crystallized emulsion ciyar da crystallization kayan aiki da aka hana a lokacin da emulsion ne da kyau pasteurized da kuma ciyar da babban matsa lamba famfo a zazzabi 5-10 ° C fiye da narkewa batu na mai lokaci.

A hankula pasteurization tsari zai bayan shiri na emulsion a 45-55 ° C hada da dumama da kuma rike jerin emulsion a 75-85 ° C for 16 sec. kuma daga baya tsarin sanyaya zuwa zazzabi na 45-55 ° C. Ƙarshen zafin jiki ya dogara da yanayin narkewa na lokacin mai: mafi girma wurin narkewa, mafi girman zafin jiki.

SANARWA, CRYSTALLIZATION DA KNEADING (ZONE 4)

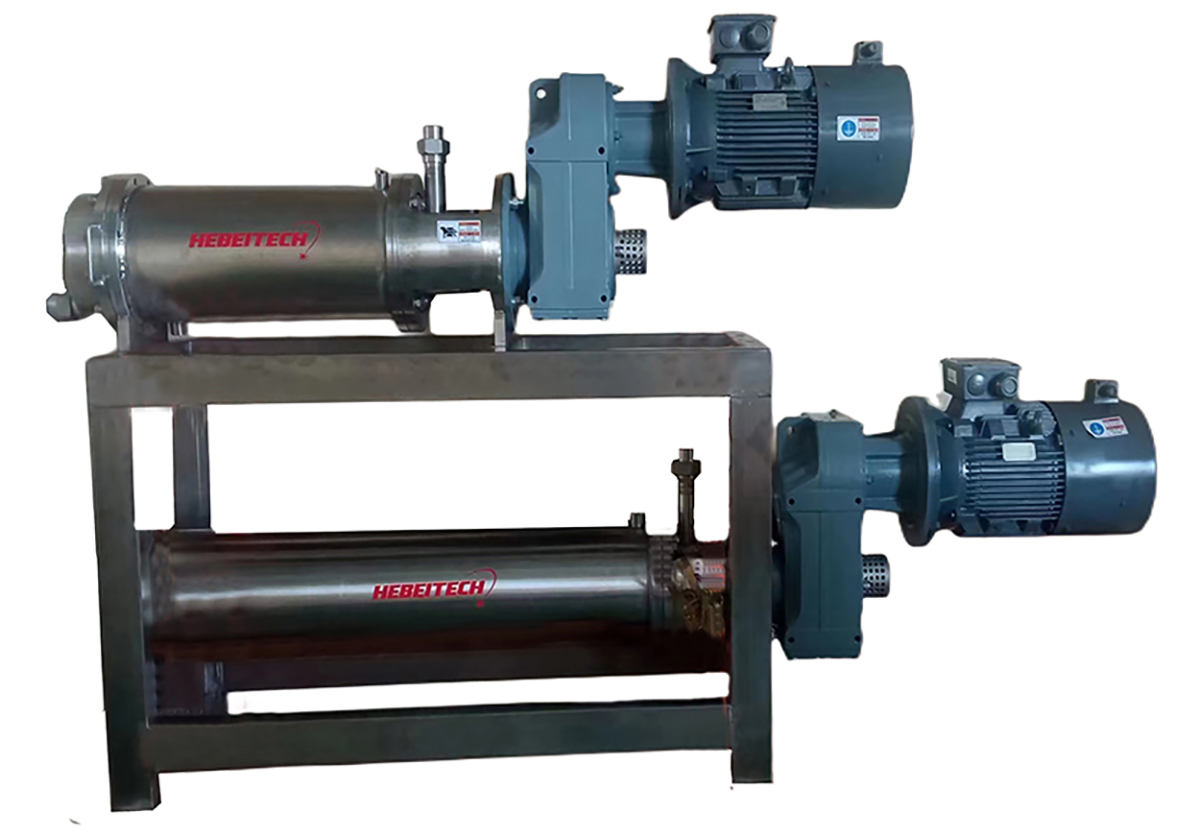

Ana fitar da emulsion zuwa layin crystallization ta hanyar babban famfo piston (HPP). Layin crystallization don samar da margarine da samfurori masu alaƙa yawanci ya ƙunshi babban matsa lamba SSHE wanda aka sanyaya ta hanyar ammonia ko Freon irin kafofin watsa labarai sanyaya. Fin na'ura mai juyi (s) da/ko kristal masu tsaka-tsaki galibi ana haɗa su cikin layi don ƙara ƙarin ƙarfi da lokaci don samar da samfuran filastik. Bututun hutawa shine mataki na ƙarshe na layin crystallization kuma ana haɗa shi kawai idan samfurin ya cika.

Zuciyar layin crystallization shine babban matsa lamba SSHE, wanda emulsion mai dumi yana da sanyi sosai kuma yana yin crystallized a saman ciki na bututu mai sanyi. Ana cire emulsion da kyau ta hanyar jujjuyawar scrapers, don haka emulsion ɗin yana sanyi kuma yana knead a lokaci guda. Lokacin da mai a cikin emulsion crystallizes, da mai lu'ulu'u samar da wani uku-girma cibiyar sadarwa entrapping ruwa droplets da ruwa mai, haifar da samfurori da kaddarorin roba Semi-m yanayi.

Dangane da nau'in samfurin da za'a kera da kuma nau'in kitsen da ake amfani da shi don takamaiman samfur, ana iya daidaita tsarin layin crystallization (watau oda na bututun sanyi da na'urar rotor fil) don samar da ingantaccen tsari na takamaiman samfurin.

Tun da layin crystallization yawanci kera samfuran kitse fiye da ɗaya, SSHE sau da yawa ya ƙunshi sassa biyu ko fiye da sanyaya ko bututun sanyi don saduwa da buƙatun layin ƙira mai sassauƙa. Lokacin samar da samfuran kitse daban-daban na gaurayawan kitse daban-daban, ana buƙatar sassauci tunda halayen crystallization na gaurayawan na iya bambanta daga wannan gauraya zuwa wani.

Tsarin crystallization, yanayin sarrafawa da sigogin sarrafawa suna da tasiri mai girma akan halaye na margarine na ƙarshe da kuma yada samfurori. Lokacin zayyana layin crystallization, yana da mahimmanci don gano halayen samfuran da aka tsara don kera akan layin. Don tabbatar da saka hannun jari don nan gaba, sassaucin layin da kuma sigogin sarrafawa daban-daban suna da mahimmanci, tunda kewayon samfuran sha'awa na iya canzawa tare da lokaci da albarkatun ƙasa.

Ƙarfin layin yana ƙayyade ta wurin sanyaya da ke samuwa na SSHE. Akwai na'urori masu girma dabam dabam dabam daga ƙananan layukan iya aiki. Har ila yau, nau'o'i daban-daban na sassauƙa suna samuwa daga kayan aikin bututu guda ɗaya zuwa layukan bututu masu yawa, don haka layukan sarrafawa sosai.

Bayan da samfurin ya yi sanyi a cikin SSHE, ya shiga cikin na'ura mai juyi na fil da / ko tsaka-tsakin crystallizers wanda aka ƙulla shi na wani lokaci kuma tare da wani ƙarfi don taimakawa wajen inganta cibiyar sadarwa mai girma uku, wanda a kan matakin macroscopic shine tsarin filastik. Idan samfurin yana nufin rarrabawa azaman samfurin nannade, zai sake shigar da SSHE kafin ya zauna a cikin bututun hutawa kafin a nannade. Idan samfurin ya cika cikin kofuna, babu bututun hutawa da aka haɗa a cikin layin crystallization.

CIKI, CIKA DA TUNAWA (ZONE 5)

Ana samun injunan tattarawa da injina iri-iri a kasuwa kuma ba za a bayyana su a cikin wannan labarin ba. Koyaya, daidaiton samfurin ya bambanta sosai idan an samar da shi don cikawa ko cikawa. A bayyane yake cewa madaidaicin samfurin dole ne ya nuna ƙaƙƙarfan rubutu fiye da cika samfurin kuma idan wannan nau'in bai yi kyau ba za'a karkatar da samfurin zuwa tsarin narkar da shi, a narke kuma a ƙara shi cikin tankin buffer don sake sarrafawa. Ana samun tsarin gyaran fuska daban-daban amma tsarin da aka fi amfani dashi shine PHE ko ƙananan matsa lamba SSHE.

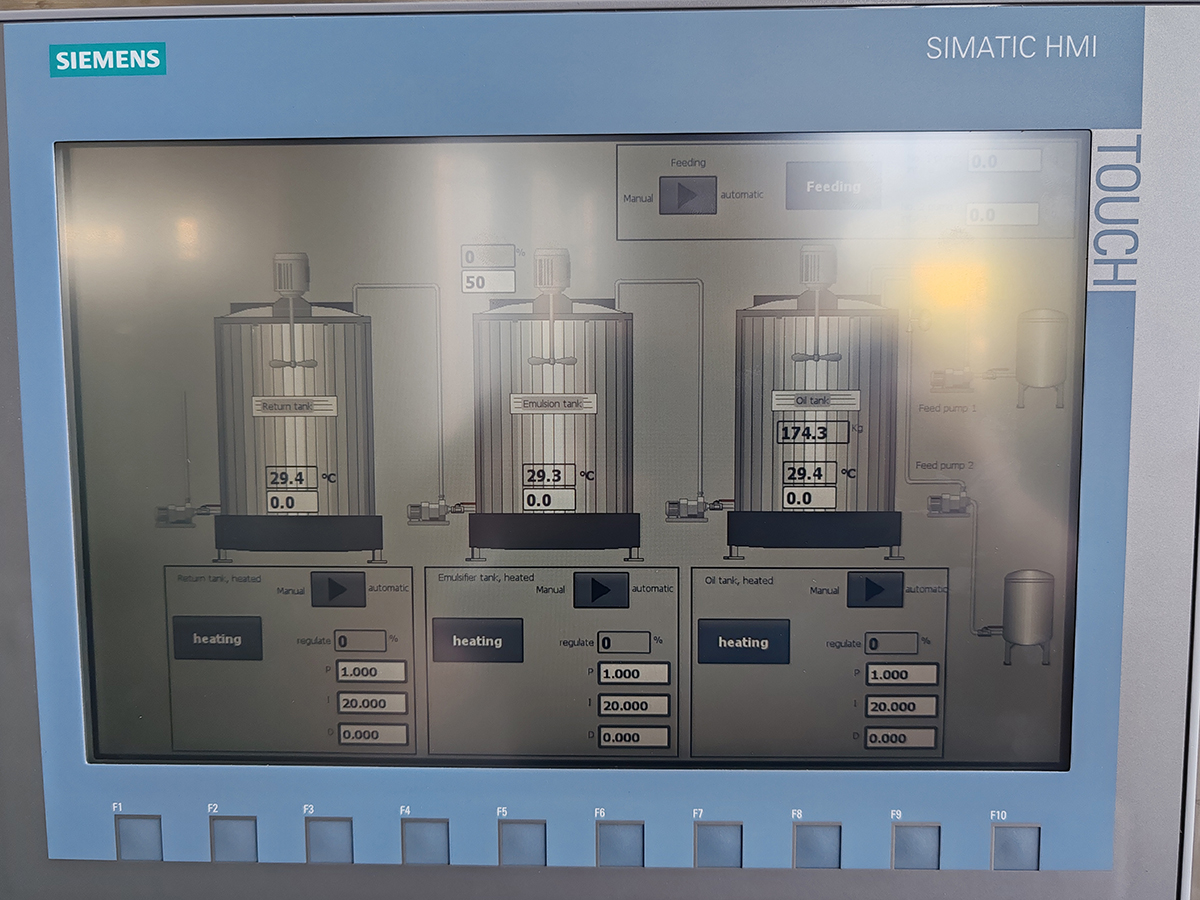

AUTOMATION

Margarine, kamar sauran kayayyakin abinci, yana cikin masana'antu da yawa a yau waɗanda aka samar ƙarƙashin ingantattun hanyoyin ganowa. Waɗannan hanyoyin yawanci suna rufe abubuwan sinadarai, samarwa da samfuran ƙarshe ba kawai a cikin ingantaccen amincin abinci ba har ma a cikin ingantaccen ingancin abinci. Ana iya aiwatar da buƙatun ganowa a cikin tsarin sarrafawa na masana'anta kuma an tsara tsarin kula da Shiputec don sarrafawa, yin rikodin da rubuta mahimman yanayi da sigogi game da cikakken tsarin masana'antu.

Tsarin sarrafawa yana sanye take da kariyar kalmar sirri kuma yana fasalta shigar da bayanan tarihi na duk sigogin da ke cikin layin sarrafa margarine daga bayanan girke-girke zuwa kimanta samfurin ƙarshe. Ƙididdigar bayanan ya haɗa da iya aiki da fitarwa na famfo mai mahimmanci (l / hour da matsa lamba na baya), yanayin samfurin (ciki har da tsarin pasteurization) a lokacin crystallization, yanayin sanyi (ko matsi na watsa labaru) na SSHE, gudun SSHE da na'ura mai juyi na fil da kuma nauyin injin da ke aiki da famfo mai mahimmanci, SSHE da fil rotor inji.

Tsarin sarrafawa

Yayin aiki, za a aika da ƙararrawa ga mai aiki idan sigogin sarrafawa na takamaiman samfurin ba su da iyaka; an saita waɗannan a cikin editan girke-girke kafin samarwa. Dole ne a yarda da waɗannan ƙararrawa da hannu kuma dole ne a ɗauki matakai bisa ga tsari. Ana adana duk ƙararrawa a cikin tsarin ƙararrawa na tarihi don kallo na gaba. Lokacin da samfurin ya bar layin samarwa a cikin madaidaicin marufi ko cike da tsari, baya ga sunan samfurin da aka yiwa alama da kwanan wata, lokaci da lambar tantance tsari don bin diddigin gaba. Cikakken tarihin duk matakan samarwa da ke cikin tsarin masana'anta don haka an shigar da su don tsaro na mai samarwa da mai amfani na ƙarshe, mabukaci.

CIP

Tsire-tsire masu tsaftacewa na CIP (CIP = tsaftacewa a wuri) suma wani bangare ne na kayan aikin margarine na zamani tun da ya kamata a tsaftace shukar margarine akai-akai. Don samfuran margarine na gargajiya sau ɗaya a mako shine tazarar tsaftacewa ta al'ada. Koyaya, don samfuran ƙima kamar ƙananan mai (abincin ruwa mai yawa) da/ko babban furotin mai ɗauke da samfura, ana ba da shawarar gajerun tazara tsakanin CIP.

A ka'ida, ana amfani da tsarin CIP guda biyu: tsire-tsire na CIP waɗanda ke amfani da kafofin watsa labarai mai tsaftacewa sau ɗaya kawai ko tsire-tsire CIP da aka ba da shawarar waɗanda ke aiki ta hanyar buffer bayani na kafofin watsa labarai masu tsaftacewa inda ake mayar da kafofin watsa labaru irin su lye, acid da/ko masu kashe ƙwayoyin cuta zuwa tankunan ajiya na CIP guda ɗaya bayan amfani. An fi son tsarin na ƙarshe tun lokacin da yake wakiltar mafita mai dacewa da muhalli kuma shine mafita na tattalin arziki dangane da amfani da kayan tsaftacewa kuma ta haka farashin waɗannan.

Idan an shigar da layukan samarwa da yawa a cikin masana'anta guda ɗaya, yana yiwuwa a saita waƙoƙin tsaftacewa daidai gwargwado ko tsarin tauraron dan adam CIP. Wannan yana haifar da raguwa mai mahimmanci a lokacin tsaftacewa da amfani da makamashi. Ana sarrafa sigogi na tsarin CIP ta atomatik kuma an shigar da su don ganowa a cikin tsarin sarrafawa.

MAGANAR KARSHE

Lokacin samar da margarine da samfuran da ke da alaƙa, yana da mahimmanci a tuna cewa ba kawai sinadarai kamar mai da kitse da ake amfani da su ba ko kuma girke-girke na samfurin wanda ke ƙayyade ingancin samfurin ƙarshe amma har ma da daidaitawar shuka, sigogin sarrafawa da yanayin shuka. Idan ba a kula da layin ko kayan aiki da kyau ba, akwai haɗarin cewa layin ba ya aiki yadda ya kamata. Sabili da haka, don samar da samfurori masu inganci, shuka mai aiki da kyau dole ne amma zaɓin kitse mai gauraya tare da halaye waɗanda suka dace da aikace-aikacen ƙarshe na samfurin yana da mahimmanci kuma daidaitaccen tsari da zaɓin sigogin sarrafawa na shuka. Ƙarshe amma ba aƙalla samfurin ƙarshe ba dole ne a kula da zafin jiki bisa ga amfani na ƙarshe.

Lokacin aikawa: Dec-19-2023