Layin Samar da Miyar Custard

Layin Samar da Miyar Custard

Layin Samar da Miyar Custard

Bidiyon Shiryawa:https://www.youtube.com/watch?v=AkAcycJx0pI

ALayin samar da miyar custardya ƙunshi jerin hanyoyin sarrafa miyar custard ta atomatik da ta atomatik don samar da miyar custard cikin inganci, akai-akai, da kuma tsafta. Ga cikakken bayani game da matakan da aka saba bi a layin samar da miyar custard:

1. Sarrafa Sinadarai da Shiri

- Liyafar Madara da Ajiya

- Ana karɓar madarar da ba a so, a gwada ingancinta, sannan a adana ta a cikin firiji.

- Madadin: Foda madara da aka sake yin amfani da ita + ruwa (don tsawon lokacin da za a ajiye).

- Gudanar da Sukari da Zaki

- Ana auna sukari, ruwan masara, ko wasu kayan zaki kuma a narkar da su.

- Sarrafa Foda da Kwai

- Ana haɗa ƙwai mai ruwa (wanda aka yi masa man shafawa) ko garin ƙwai da ruwa.

- Sitaci & Masu Daidaitawa

- Ana haɗa sitacin masara, sitacin da aka gyara, ko kuma mai kauri (misali, carrageenan) kafin a haɗa su don hana taruwa.

- Abubuwan dandano da ƙari

- Ana shirya vanilla, caramel, ko wasu dandano, tare da abubuwan kiyayewa (idan akwai buƙata).

2. Haɗawa da Haɗawa

- Rukunin ko Ci gaba da Haɗawa

- Sinadaran suna haɗuwa a cikininjin haɗa kaya mai ƙarfikotankin hadawa na farkoa ƙarƙashin yanayin zafi mai sarrafawa (don guje wa kauri da wuri).

- Ana iya amfani da Homogenization don laushin rubutu.

3. Dafa Abinci & Man Shafawa

- Ci gaba da Dafa Abinci (Mai Canja Zafin Sama Mai Gogewa)

- Ana dumama cakuda zuwa75–85°C (167–185°F)don kunna gelatinization na sitaci da kuma kauri miyar.

- Pasteurization (HTST ko Batch)

- Gajeren Lokaci Mai Zafi Mai Tsayi (HTST) a72°C (161°F) na daƙiƙa 15-20ko kuma yin amfani da batch pasteurization don tabbatar da tsaron ƙwayoyin cuta.

- Matakin Sanyaya

- Sanyaya cikin sauri zuwa4–10°C (39–50°F)don dakatar da girki da kuma kiyaye yanayinsa.

4. Haɗakarwa (Zaɓi ne)

- Homogenizer mai matsin lamba mai yawa

- Ana amfani da shi don laushi mai laushi (yana hana ƙwaya).

5. Cikowa da Marufi

- Injinan Cikawa ta atomatik

- Ciko jakar(don siyarwa) kocikawa mai yawa(don hidimar abinci).

- Cika Aseptic(don tsawon lokacin shiryawa) kocike da zafi(don ajiyar yanayi).

- Tsarin Marufi:

- Kwalaben filastik, kwalaye, jakunkuna, ko gwangwani.

- Ana iya amfani da sinadarin nitrogen don ƙara tsawon lokacin shiryayye.

6. Sanyaya da Ajiya

- Busasshen Barci (idan ana buƙata)

- Don kirim mai sanyaya, sanyaya cikin sauri zuwa4°C (39°F).

- Ajiya Mai Sanyi

- An adana a4°C (39°F)don sabon kirfa ko yanayi don samfuran da aka yi wa magani da UHT.

7. Kula da Inganci da Gwaji

- Duba Danko(ta amfani da na'urorin aunawa).

- Kula da pH(maƙasudi: ~6.0–6.5).

- Gwajin Kwayoyin Halitta(jimillar adadin faranti, yisti/mold).

- Kimantawar Hankali(ɗanɗano, laushi, launi).

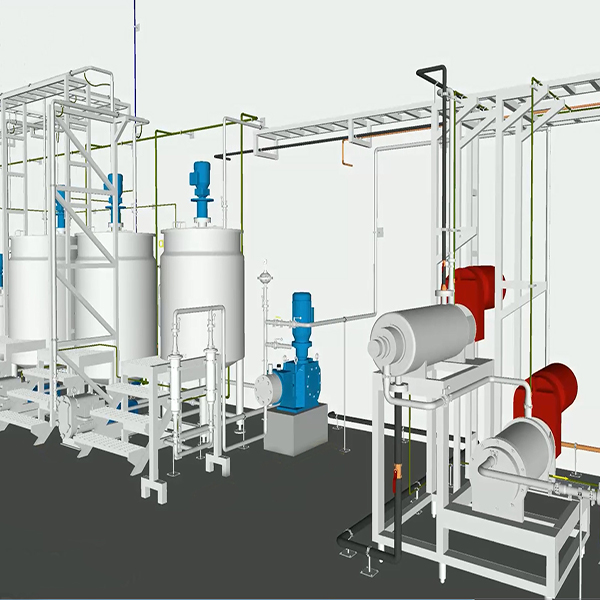

Kayan aiki masu mahimmanci a Layin Samar da Miyar Custard

- Tankunan Ajiya(don madara, sinadaran ruwa).

- Tsarin Aunawa & Dosage.

- Tankunan Haɗawa Masu Tsabta da Tsaftace Tsafta.

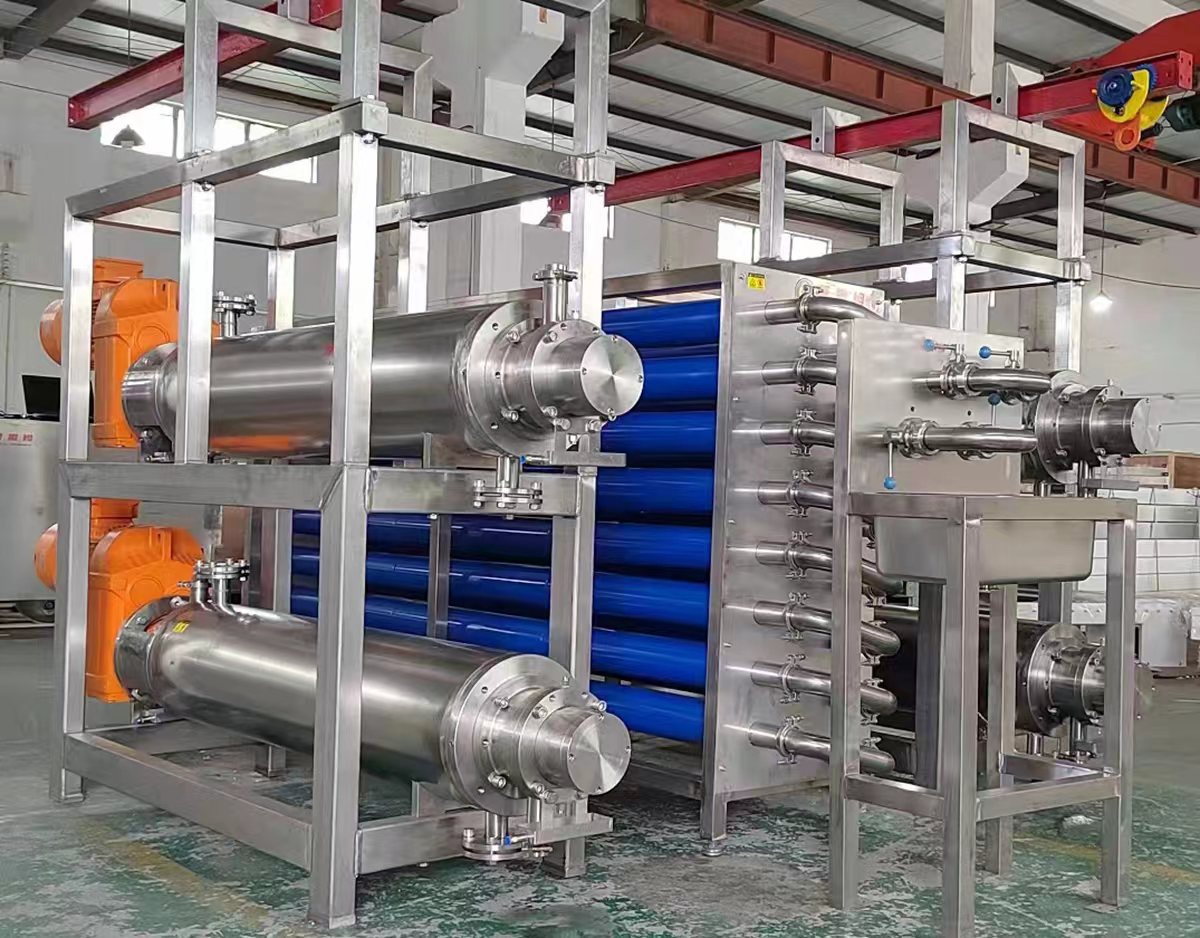

- Pasteurizer (HTST ko Batch).

- Ma'ajiyar Zafi ta Sama da Aka Goge (don girki).

- Homogenizer (zaɓi ne).

- Injin Cika (piston, volumetric, ko aseptic).

- Rafukan Sanyaya.

- Injinan Marufi (hatimi, lakabi).

Ire-iren Miyar Custard da Aka Samar

- Custard mai sanyi(ƙarshen lokacin shiryawa, ɗanɗano sabo).

- UHT Custard(tsawon lokacin shiryawa, an yi masa allurar rigakafi).

- Hadin Custard Mai Foda(don sake ginawa).

Aiki da Kai da Inganci

- Tsarin Kula da PLCdon daidaitaccen sarrafa zafin jiki da haɗuwa.

- Tsarin CIP (Tsabtace-cikin-Wuri)don tsafta.

Aikin Gudanar da Rukunin Yanar Gizo

Rubuta saƙonka a nan ka aika mana da shi